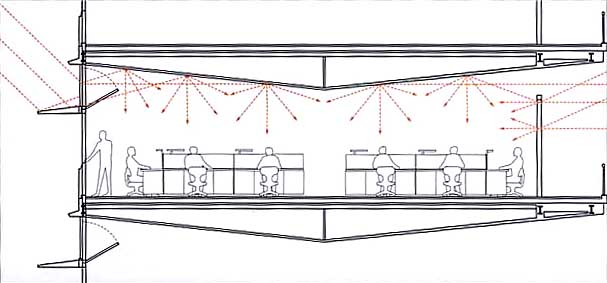

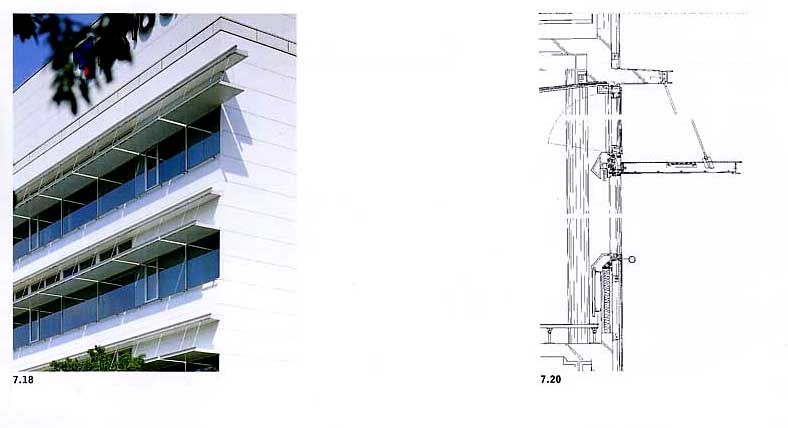

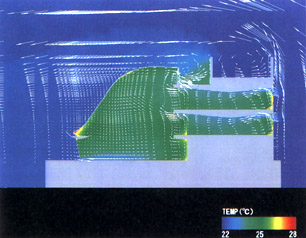

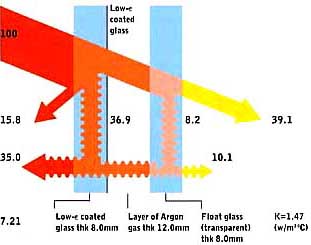

| Planned control of heat, cold and sunlight - Building exterior uses light shelves and double Low-e glass For persons inside buildings, burdens places on the air conditioning system as a result of direct sunrays and extreme outdoor temperature changes can lead to unpleasant conditions indoors. The large windows on the south side ( height: 3.4 m ) and the glass-walled ecological core on the north side provide the offices with ample daylight. Light shelves above the windows on the south side prevent direct sunlight from getting into the offices. These windows and the glass-walled ecological core use high-transparency low-e double glazing with very high heat insulation properties (Uwinter=1.49W/m2K). Sunlight reflected from the upper surfaces of the light shelves enters the rooms through fanlights, automatic ventilation windows and illuminates the sloped light-reflection ceilings. The size of the light shelves here are designed to account for the sun's position throughout the year: sunrays are blocked during summer months, and allowed to enter during winter. Low-energy, highly insulated glass lets visible light rays in, but prevents outdoor heat from entering. Drawing in the light Traditionally, direct sun, despite its obvious advantages, has always posed a design challenge for architects because of its variability. The standard office building typically uses artificial light sources for both ambient and task lighting, utilizing window shades or tinted glass panes to block natural light. The architects took a contrary position, namely that the movement of natural daylight is a very desirable stimulus and makes spaces more attractive. It allows dramatic reductions in the energy that would be consumed by artificial lighting. Controlling Luminance Utilizing the Hisashi or light shelves The

window bays on Earth Port's south facade were designed to

uniquely pair the traditional Japanese hisahi, a shading

eave, with various sophisticaed glass technologies. the

ceiling on this aspect of the building slopes from 3.5m

high at the windows to 2.8m in the centre of the space.

Light shelves, 1.2m deep, were fitted above the middle of

the windows. The sun, reflecting from the lightshelf,

passes through diffusion glass on the office partitions to

reach the rooms' centre and brightens the ceiling. This

combination gives a greater subjective feeling of

brightness as well as increasing sustained illumination

within the room.

Closer cooperation with nature The "ecological core" of the building is a glass-bounded well of open space in the center that is designed to bring soft light from the sky into the offices. The southerly windows come with heat shelves that block direct sunlight while delivering a suitable quantity of natural light into the office space. Thanks to methods such as these, electric lighting power can be reduces to one-third the ordinary amount. The ecological core is also used for natural ventilation, which contributed to lowering heating and cooling energy consumption. For ventilating purposes, there are openings at the top of the core, and high windows in the offices on the south side of the building. During the mild intermediate seasons, the automatic ventilation windows are open and outside air is introduced into the building. The building has good natural ventilation regardless of wind directions and speeds. This is caused by the stack effect and by the induction effect of the ventilation tower. Through this arrangement's "chimney effect," an air flow can be created even when there is no wind blowing; this also eliminates any necessity to use fans. Besides, natural ventilation is used at night time. The success of the

Ecological Core

More efficient use of technology

Other energy saving measures

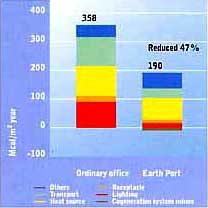

The entire aforementioned heating, ventilation, air-conditioning, and lighting system is monitored by a building energy and environment management system (BEMS), which eliminates hidden energy waste, thereby optimising the operation of the system. To extend the service life of the building, a highly durable glass-based material is used for the exterior wall. However, more effective measures are the ones enhancing flexibility in addressing ever-changing future needs, such as deep ceiling-and underfloor support spaces that make it easier to modify piping and wiring. The Situation

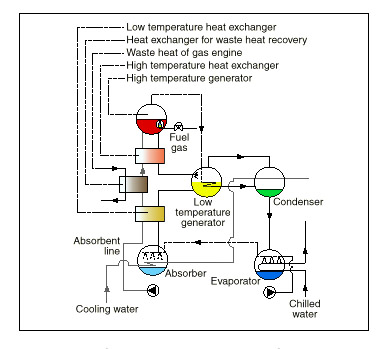

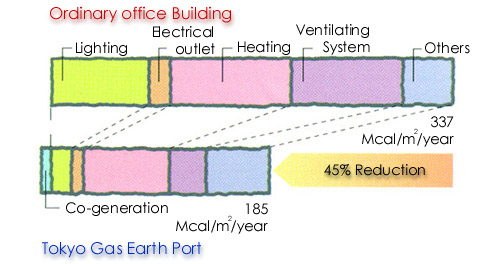

The collected data on the energy consumption indicated that the expected energy-saving effects were attained. For example, in the offices on the fourth floor, natural lighting reduced the electricity consumption by 58% from August 1996 through January 1997. Similarly, the natural ventilation reduced the energy consumption of air conditioning by 30% in October 1996. The specific primary energy consumption of 219 W/m2 (787 kJ/m2h) in the ecological core is less than that of a supposedly perfect heat-insulated showroom performing the same function (225 W/m2 ; 811 kJ/m2h). This demonstrates that the energy gained from using daylight completely covers the energy loss through the transparent glass wall. From August through September 1996, the cogeneration system operated at an average efficiency of 27.1% in power generation and 47.4% in waste-heat recovery (based on the heat actually used), recording an overall efficiency of 74.5% (LHV). Moreover, the cogeneration system supplied 10% of the building's power needs.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||