|

|

| |

Design Features:

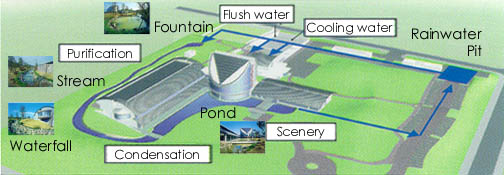

This international research facility was built with the purpose of developing environment protecting technologies for all the world. In order to produce such technologies, the facility design itself includes many examples of methods and materials that reduce the burdens places on the environment. Among these are fountain, stream, waterfall and pond which not only enhance the facility's scenery, but also store rainwater, which is used for cooling heat sources. This cooling system produces about a 20% saving in energy consumption. In addition, thanks to a natural filter bacterial film that is produced by the organisms growing on the crushed stone placed at the bottom of the brooks and ponds, the water is purified without having to use a high-level filtering system. |

|

| Control of heat and sunlight: |

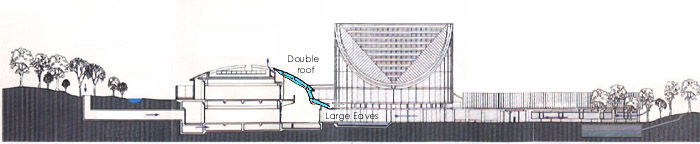

| Semi-buried structure |

To utilize thermal insulation and constant temperature nature of the earth to reduce thermal loads on external walls |

| Eaves |

Large eaves to block direct solar heat gain in summer |

| Double skin |

Multi-layer glazing and double roof to ensure high thermal resistance |

| Under-floor air-conditioning |

Reduced air-conditioning cooling loads for habitable areas |

(Click to have a larger view) (Click to have a larger view)

| Communication with nature |

| Air monitor ventilation |

Air monitors to enhance ventilation effectiveness (by CO2 concentration measurement) |

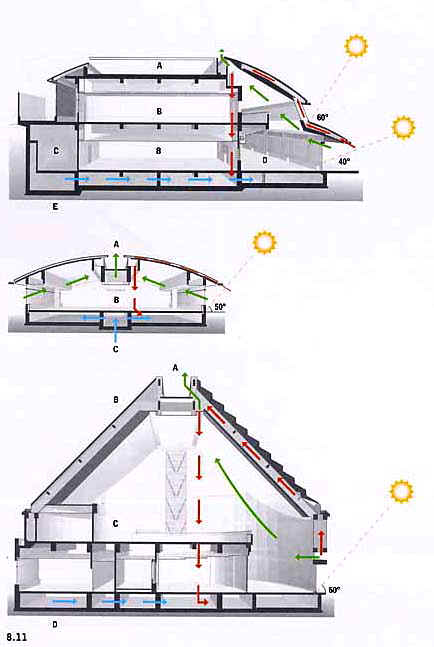

| Air flow roof |

Outdoor air is warmed in a double roof (which is warmed by sunlight) and then taken into the building for heating in winter |

| Cool tube |

Outdoor air is cooled in an underground pit (which is cooled by the low temperature of the earth) and then taken into the building for cooling in summer |

| Efficient use of energy |

| Heat storage by building structure |

Surplus heat is stored in the building structure to reduce air-conditioning starting load |

| Utilization of large temperature difference |

Hot and chilled water is used in large temperature difference |

(Click to have a larger view) (Click to have a larger view)

| New energy system |

|

| Solar photovoltaics |

50 kW solar photovoltaic panels (total area 427 m2) are installed on the roof of atrium (87 m2) and laboratory (340 m2) |

| Fuel cells |

50 kW town-gas powered fuel cell are installed |

|

Capturing

the sun

Natural sunlight in the work and dwelling

environment provides as soothing and peaceful

radiance unmatched by artificial lighting. As it

changes with passage of the day, it evokes a

range of moods in those it touches. The shoji

screens of traditional Japanese houses produced

a discrete and malleable light that varied in

response to the hour, to the season, and to the

layers of screens that were either open or shut.

Via these simple frames, and entire house could

be open to the elements on two sides, or

selected areas closed off to let the sun

permeate through the rooms in subtle

patterns.

The atrium in the building's centerpiece

tower integrates the sun in a similar manner. It

has a high sloped cathedral-scale roof that also

serves as a solar energy 'platform'. Unique in

its design, the entire surface is covered with

photovoltaic cells used for both electricity and

as roofing materials. The interior has shoji

screens surrounding the reading room on the

second floor while the tower's circular windows

provide a magnificent vista of still water,

manicured lawns and avenues of trees.

Size and angles of large eaves and window pane materials are selected for optimum thermal efficiency and to enable sunlight to deliver as much of the building's various lighting requirements as possible. Solar photovoltaic panels of total capacity 50 kW are installed to meet 2.5% of total power demand. |

Wind and airflow

In summer, large eaves will shade out the strongest sunlight, and the fresh intake air for the air-conditioning system will be taken from a underground pit that remains cool through contact with the earth. In winter, the fresh intake air for the air-conditioning system will be taken from the ceiling space, which is warmed by sunlight. This results in energy savings equivalent to 10% of outdoor air load.The roof of the lab block, just like an aircraft wing,

is bevelled for maximum airflow capacity. This

surface effectively reduces cooling loads by

forming deep eaves and increasing the volume

and direction of airflow for enhanced

ventilation. The evaes are extensive enough to

protect the laboratories from sunlight. The

roof is also constructed of two layers of

materials that increase the insulation

performance and provide comfortable interior

for temperatures for labs and offices. In

summer, the acculated heat between the two

layers is expelled naturally by the wind flow

along the roof created by the temperature

gradient. During winter, warmed air harvested

between the two layers of recirculated for

heating. This ventilation method is based on

chimney systems used in traditional japanese

houses. Additional airflow in the laboratories

is supplied by floor-vented air conditioning.

Air is propelled from floor to the ceiling,

forming a buoyant layer as it is gradually

heated by thermal radiation emitted from lab

workers. computers, lights and equipment. On

reaching maximum buoyancy, the heat is

extracted from the room via the ceiling vents.

This is a highly-effective configuration for

ventilation and air-conditioning based on the

considerable speed of ascending warm air, and

provides the lab workers with an equable and

pleasant working temperature. When air

buoyancy is used for heat extraction, thermal

radiation can easily be eliminated from any

environment fuel-consuming methods.

|

| |

Energy from the

motility of water

The building is located on an open hill. Taking advantage of the sloped site, a system was adopted in which rain water collected on site is subsequently recycled and circulated in the springs, brooks, waterfalls and ponds created around the building. The result is a landscape as restful as it is beautiful. The collected rainwater is used as cooling water for the air-conditioning system and then recycled for use in flushing toilets or it is circulated within the site for purification by natural filtration. This improves the efficiency of heat pump unit by 20% and reduces city water consumption by 20%.

Exhaust heat from the air conditioning system is transferred to water and discharged into a brook, where it is naturally cooled. This "cooling river" system significantly cuts down the energy consumed for air conditioning. This provides further evidence that running water is valuable not only for creating a cool atmosphere but also for the more practical reason of energy conservation.

In addition, RITE has a very active

Carbon Dioxide Ocean Sequestration programme,

and their concern for global water resources

is reflected in the ways water is integrated

into design of the facility. Water

circulates around the entire site,

fulfilling a number of roles at various

locations. It passes through streams,

waterfalls and pond areas to produce a

reflective and serene panorama. Beyond its

aesthetic appeal, the water is also used as

a primary agent in the building's cooling

system. The pond, stream and waterfalls

combine to form a natural cold conduit. Hot

water released from the cooling equipment is

relayed out to the pond where it is exposed

to the atmosphere. As the water gathers

speed, the heat evaporates. The stream

splashes down artificial dams and decorative

rocks as it winds through the garden. It

cascades and foams over shallow falls and is

returned to the system to be recycled for

cooling purposes.

The conserved water is also used for a

number of functions within the building.

This energy conversion method of exploiting

the migratory properties of water is among

the best of the building's 'green'

features.

|

|

| |

Fuel cells:

Fuel cells, developed originally for space vehicles, are being explored for their potential in commercial applications as an energy system. They are especially beneficial as urban cogeneration system which supplies both electricity and heat. Fuel cells produce electricity and water by the reaction of hydrogen and oxygen, which is the reverse of water electrolysis. Hydrogen is produced by the natural gas reforming process, while oxygen is obtained from the air. Since electric energy is

directly obtained from the chemical reaction of hydrogen and oxygen, electrical efficiency is higher than conventional power generating methods. The specifications of the fuel cell system installed in the RITE headquarters building is given as follows: |

|

| Manufacturer |

Fuji Electric |

rite50.jpg 55.85 Kb

(Fuel cell principle)

rite51.jpg 152.57 Kb

(Schematic)

rite52.jpg 19.86 Kb

(Fuel cell unit)

|

| Rated power |

50 kW AC |

| Voltage |

200/220 V |

| Electrical efficiency |

40% (LHV) |

| Overall efficiency |

80% (LHV) |

| Heat recovery |

90 oC and 55 oC hot water |

| Fuel |

City gas 13A, low pressure |

| Operation |

Grid-connected |

| NOx |

below 5 ppm |

| Dimensions |

1.75 (W) x 3.1 (L) x 2.2 m (H) |

| Weight |

6.5 tons |

|