|

|||||||||||||||||||||||||||||||||

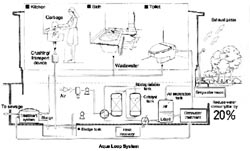

Towards a Future Vision of Housing that is Urban Environment FriendlyA closed system that reduces the load placed on the environment. As long as people have lives to lead, various waste products and wastewater will be generated. Looking at the garbage problem alone, the waste index has increased by about 15% in Japan in the five year period since 1985. Comfort required in city life has led to this increase in waste, and consequently has created various problems that include the deterioration of the environment, the drying up of reclaimed land, and exhaust caused by incineration. The garbage problem is a major problem that must be solved before the 21st century. Various ways of combating this issue are being proposed -- non-generation of garbage, collection and recycling of garbage as a natural resource, and effective utilization of water resources. This will, of course, require the combined efforts of those living in cities. At NEXT 21, a number of support systems are being developed -- a closed treatment system for garbage, and a garbage and wastewater treatment system capable of reducing the load on the sewerage system. 1.1 Garbage Crushing/Transporting Statistics show that about 40% of the waste produced in households is garbage. At NEXT 21, this garbage is collectd in a special receptacle located in the kitchen sinks of each household, and is sent to an adjustment tank in the basement by a garbage crushing/transporting device located under the kitchen. 1.2 Biological Garbage Treatment Besides a large-scale garbage treatment system for the whole building, garbage treatment systems capable of handling general household garbage are provided for two households at NEXT 21. One of these systems reduces the time taken in the biological fermentation processing by heating the gas for maintaining stable performance. The other separates solids and liquids in the garbage, and reduces the volume of garbage by forced hot air drying. 1.3 Recycling Cans and Plastic Waste such as cans and paper generated in households also can be recycled. Trash bins for sorting this waste are provided in each household. Compactors are provided in common spaces of the project for flattening cans and reducing wasted space, and steel and aluminum cans are automatically separated. Compactors for reducing the size of plastic and other bulky waste also are provided in some households. Currently, in most homes, raw garbage is collected in the kitchen, and then carried together with paper, plastic and other rubbish by refuse carts to refuse plants where it is then incinerated. Excess sludge that is generated by the biological treatment system is discharged by a vacuum refuse collector, and treatment at an outside treatment plant. At NEXT 21, we have installed an experimental "closed treatment system" for treating garbage and excess sludge on site in an "AQUALOOP" system -- a catalytic wet oxidation system.

2.1 Wastewater Treatment System Wastewater collected from kitchen, bath, toilet, etc. is treated by a contact aerating biological treatment system. 2.2 Water Reclaim System Some of the biologically treated water and the water treated at the

AQUALOOP System passes through a reclaimed water treatment system that

applies active carbon treatment, and is used as rinse water, etc. in toilets.

At NEXT 21, use of this reclaimed water is intended to reduce the amount

of clean water used.

3. Use of Pre-cast and Recycled Components At NEXT 21, the problem of conserving natural resources is being tackled at the building stage. In actual terms, greater use of pre-cast building components is being promoted in order to reduce use of casts for concrete pouring made of wooden panels. Various other measures are being adopted for conserving natural resources. These include the use of floor blocks that utilize final waste products from sewerage treatment processes as aggregate, and the recycling of FRP, a substance regarded as a pollutant, for use as the raw materials for baths.

Achieving Energy Conservation from a Total Housing Perspective Building a highly efficient system around fuel cells. Up till now, we have been able to lead comfortable lives while relying mostly on imported energy sources such as petroleum, coal and natural gas. It is forecast that the energy requirement for households in Japan will increase in the future, too. At NEXT 21, we have developed a co-generation system for housing around fuel cells, in order to make our lives more comfortable and minimize energy usage. Natural energy sources such as solar rays will be effectively utilized, and energy wastage kept to a minimum by improving the efficiency of heat insulation. By integrating these methods, we have achieved energy savings of 30% at initial conversion. This "Total Energy System" is environmentally friendly with NOx and CO2 emissions reduced by 70% and 20%, respectively. 4.1 Outline of the System NEXT 21 adopts a total perspective regarding the energy required for sustaining our lives -- hot water supply, air conditioning, and in all other aspects. The Total Energy System aims to achieve an energy savings pf about 30% compared with that of conventional systems, and it is hoped that ultimate efficiency in energy usage will be achieved. To this end, this system incorporate the following measures:

All of the energy systems at NEXT 21 are controlled by an energy system controller (ESC) in order to achieve maximum operating efficiency. The ESC forecasts the loads placed on the electrical and thermal systems, and automatically controls the entire energy system so that the energy consumption is kept to a minimum. To be more precise, the ESC forecasts the heating and cooling loads, electrical power loads, and the amount of electrical power produced by the solar cells. It then creates an optimum operating schedulem, determines the operating capacities of the fuel cells and other facilities, and issues the required control signals. Also in order to increase control accuracy, control instructions are expected every 15 minutes while compensating for control error. 4.3 Absorption Chiller-Heater

4.4 Solar Photovoltaic Solar cell panels (total 7.5 kW) are situated on the roof top at NEXT

21. Though the output of solar cells is effected by the amount of

sunshine and the weather, the advantages of the solar cell are fully demonstrated

in the Total Energy System.

4.5 Thermal Energy Systems The core of the Total Energy System is the fuel cells. From this fuel cell cogeneration system, two types of thermal energy can be extracted: 160 deg C high-temperature steam, and 55 deg C low temperature hot water. the high-temperature steam is for making the chilled and heated water for use in air-conditioning. This is achieved by the steam-driven dual-effect adsorption chiller-heater. High- and low-temperature hot water storage tanks are provided in the hot water supply system. The low-temperature waste heat of the fuel cell and heat recovered from the garbage treatment system is stored mainly in the low-temperature hot water storage tank for preheating hot water. high-temperature waste heat can be stored in the high-temperature hot water storage in the high-temperature hot water storage tank when little load is placed on the air-conditioning system or during intermediate periods. 4.6 Electric Power System Electricity at NEXT 21 is supplied by a "self-contained power supply system" comprising 100 kW Fuel Cells, 7.5 kW Solar Cell, and 1000 Ah storage batteries. When DC power from these power supplies is converted to AC by an inverter, an energy loss results. At NEXT 21, the three DC power supplies directly provide DC power to electrical equipment such as common lighting, elevators, and pumps that can be run on DC power, thus increasing the efficiency of power supply facilities. 4.7 Fuel Cells Fuel cells have been well known as power supplies for spaceships since Germini, Apollo and the Space Shuttle in use today. In a fuel cell, an inverse reaction of water electrolysis is caused to produce electricity and water. So that DC power energy can be obtained directly from the reaction between hydrogen and oxygen, fuel cells have a high generating efficiency.

Also, fuel cells generate little NOx and SOx,

so they are expected to become core elements in cogeneration systems in

the 21st century.

5. Building Energy Performance 5.1 Airtightness and Insulation Energy that is wasted when cooling or heating houses can be minimized by limiting how much heat and air is escapes where we live. An example of this is the R-2000 house. Here, natural ventilation is carried out about 0.05 times per hour, whereas general wood construction housing must be naturally ventilated about 1.5 times per hour. At NEXT 21, total heat insulation is maintained while providing sufficient wide windows, and satisfactory air quality is ensured by a highly efficient ventilation and air-conditioning system. In order to evaluate the relationship between insulation, air-conditioning load, and energy consumption, two sets of heat insulation specifications are applied. Specifications conforming to energy saving standards in Japan are applied on the 3rd and 4th floors, while specifications conforming to R-2000 standards are applied on the 5th and 6th floors. NEXT 21 Housing Heat Performance Criteria

5.2 Energy Produced and Consumed

The first two figures in above show the outputs for the fuel cells and the photovoltaic rooftop array for the period between April 1994 and August 1996. The third chart in the right hand side profiling the monthly demand and use of energy for heating, cooling, and hot water shows the highest consumption occurring in the summer. Through simulation analysis, the study also compared the facility to other buildings. One of these is normally insulated and has a conventional HVAC system; the other has a conventional HVAC system but is insulated to the equivalent of NEXT21. The comparison revealed that the fuel cell energy system of NEXT21 produces a 27 percent savings over the standard insulated building (17 percent was attributed to insulation an 10 percent to the energy system itself). The study noted that the total energy system of the facility places a lighter load on the environment than more traditional systems. For example, the NEXT21 system results in 74 percent less of NOx gas production than a traditional building (56 percent of this reduction is attributed to the energy system and 18 percent to the insulation). 6. Innovative HVAC Systems

Towards the Creation of More Comfortable Indoor Environments The major different between housing so far and the NEXT 21 lies in the fact that NEXT 21 is highly air-tight, heat-insulated housing designed for conserving energy. We felt that a ventilation system for creating a pleasant air environment would be needed to maintain a high level of comfort. In order to address this theme, we are developing new technology and equipment, operating an experimental enhanced-efficiency air-conditioning system, and are developing heat source equipment designed to save energy. 6.1 "24-hour" Operation Conventional intermittent air-conditioning systems produce a considerable load when cooling or heating is started. However, with the system in use at NEXT 21, waste heat is collected while the inside of the building with its large heat capacity is ventilated, and the indoors can be maintained at a steady temperature at all times. This system has the following advantages:

At NEXT 21, besides a 24-hour ventilation and air-conditioning system, various new air-conditioning systems are being put into practice in order to create a more comfortable environment.

Air-flow windows: The radiating heating/cooling system supplies air from ceiling radiating panels during cooling, and from floor located blow-out ports during heating. Exhaust air is discharged via air-flow windows (doubled glazed windows with built-in blinds). This brings the surface temperature of windows close to room temperature, and allows exhaust air heat to be recovered.

This distributed type air-conditioning system can be used both in multi-family and detached housing. Capable of heating and cooling about three rooms, this system supplies chilled and heated water to indoor units in each room. This gas absorption type air-conditioning system is used in some of the households at NEXT 21. 6.4 Condensing Boiler It is widely held that the efficiency of modern-day gas water-heaters

is about 80%, and cannot be exceeded using current technology.

However, condensing boilers break this heat efficiency barrier.

A condensing boiler collects condensed latent heat generated when water

vapour in the exhaust air is converted to water, which further improves

the heat efficiency of boilers by 10 to 15%. A condensing boilers

is also used at NEXT 21. |

|||||||||||||||||||||||||||||||||

After being

mixed with air, and heated and pressurized to a fixed temperature and pressure,

the wastewater is fed to a solubilization reactor. Here, solid substances

are solubilized. Next, solubilized liquid is fed to the catalyst

reactor, and the organic substances are finally oxidized into carbon dioxide,

water and nitrogen gas after being converted to intermediate products such

as low-molecular carboxylic acid.

After being

mixed with air, and heated and pressurized to a fixed temperature and pressure,

the wastewater is fed to a solubilization reactor. Here, solid substances

are solubilized. Next, solubilized liquid is fed to the catalyst

reactor, and the organic substances are finally oxidized into carbon dioxide,

water and nitrogen gas after being converted to intermediate products such

as low-molecular carboxylic acid.

At NEXT 21 we

consider that chilled and heated water for air-conditioning can be efficiently

supplied. Waste heat is effectively used as two 7 TR steam-driven

absorption chiller-heater produce chilled and heated water using high temperature

waste heat (160 deg C) from the fuel cells. Also when there is insufficient

waste heat in high-load situation, a highly efficient 30 TR gas absorption

chiller-heater is used in conjunction with chillers COP 1 and 2.

Moreover, Freon gas is not used at all, which makes the entire system an

environmentally friendly air-conditioning heat source system.

At NEXT 21 we

consider that chilled and heated water for air-conditioning can be efficiently

supplied. Waste heat is effectively used as two 7 TR steam-driven

absorption chiller-heater produce chilled and heated water using high temperature

waste heat (160 deg C) from the fuel cells. Also when there is insufficient

waste heat in high-load situation, a highly efficient 30 TR gas absorption

chiller-heater is used in conjunction with chillers COP 1 and 2.

Moreover, Freon gas is not used at all, which makes the entire system an

environmentally friendly air-conditioning heat source system.

A large-scale

absorption type chiller-heater system has been introduced at NEXT 21.

The functions of large-scale systems have been incorporated as in a compact

gas absorption type air-conditioning system for home use that does not

use Freon gas.

A large-scale

absorption type chiller-heater system has been introduced at NEXT 21.

The functions of large-scale systems have been incorporated as in a compact

gas absorption type air-conditioning system for home use that does not

use Freon gas.